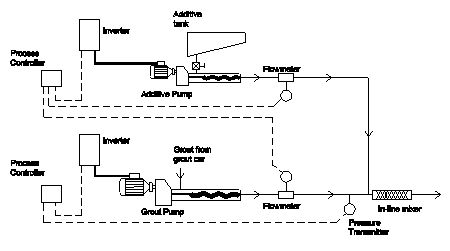

The system is primarily designed for the back-grouting of ring segments in tunnels. The main grout pump can be set to keep a pressure or flow, and the additive pump will automatically maintain the correct proportional flow. The diagram shows the main components of the system.

Tunnel Grouting System

In this typical system, the Grout pump takes its supply from a rail car, and pumps it through a flowmeter and pressure transmitter to the inline mixer. In this application the process controller measures the grout pressure and adjusts the speed of the pump, using an inverter drive, to maintain a steady pressure to the back of the ring segments. The signal from the Grout flowmeter is fed to the process controller which regulates the speed of the additive pump. This controller determines the flow that the additive pump should produce to maintain the correct proportion of additive to grout, and regulates the additive pump speed to achieve it.

The principles behind this system are transferrable to other grouting requirements where additives are metered at set proportions to other products.

Base parameters for injection can also be set to control by flow rate instead of maintaining pressure.