What is the definition of a colloidal mixer?

A true colloidal mixer utilises a mil that applies a shearing effect on the media particles, usually cement. Several competing systems use a centrifugal pump to simulate this effect, though this method in reality primarily serves to act as a circulation pump, without the high degree of shearing found in a colloidal mixer.

Why use a Colcrete colloidal mixer?

The quality of the grouting depends greatly on the effectiveness of the mixer used. The Colcrete Colloidal Mixer is the leading colloidal mixer in the industry and is recommended by most grouting experts around the world.

Description of colloidal mixing (Reschke 1998)

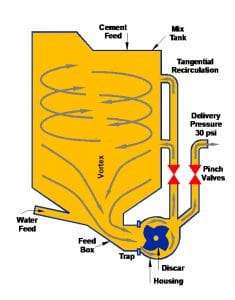

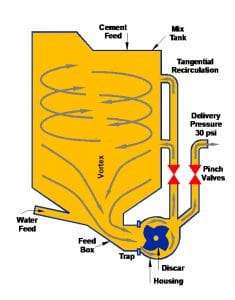

The key element of the colloidal mixer is the colloidal mill. The mill comprises a high speed rotor (or Discar) operating at 2100rpm, inside a close fitting chamber housing. The Discar is free to float horizontally on its mounting shaft with the internal fluid pressures centralising it in the housing. The clearance between the Discar and the housing is approximately 3mm. It is here that a violent turbulence and high shearing action is created which is capable of breaking down clusters of dry cement particles called agglomerates.

The colloidal mill also creates centrifugal force to further mix the grout, and which is capable of generating a maximum discharge pressure of 200kPa and a flow rate up to 850l/min. It is possible to increase the mill’s efficiency as a pump (thus giving a higher pressure capacity) but this would reduce its efficiency as a mixer.

Depending on the required batch size of the mixer, up to four colloidal mills can be used per mixing tank. Each mill requires a suitably rated power source (Diesel, Electric, Hydraulic or Pneumatic).

- Proven Technology. As the innovators of the system back in the 1930’s Colcrete Colloidal Mixers are used in more than 100 countries. They are thus internationally recognized as the most efficient method of mixing cement based grouts and other materials, resulting in very stable mixes, which resist bleed and contamination by groundwater due to the high water absorption rate.

- Higher Strength. The colloidal mixing action can mix grouts of lower water/cement ratios than that mixed by more conventional methods, resulting in grout with higher.

- Optimum Mixing. The cement and water are repeatedly re-circulated through the mixer’s high shear zone. This breaks down the clusters of dry particles (agglomerates) and ensures an even dispersion of fluids and solids.

- Minimal Bleed. The combination of low water/cement ratios and efficient grout mixing ensures that more of the water is absorbed by hydration, therefore minimizing bleed. Every particle of cement is thoroughly wetted and separate with no flakes or clumps.

- Immiscible with Water. A critical property of colloidally mixed grout is that dilution in water is minimal. This makes it ideal for underwater grouting or for grouting anchors in water bearing ground conditions.

- Minimal dilution by groundwater. BS8081 recommends the use of high shear mixing for the grouting of anchors in water bearing ground conditions because the dilution in minimised.

- Rapid mixing of grouts containing sand. Up to a sand/cement ratio of 4:1 and neat cement grouts with water/cement ratios as low as 0.36:1 without additives, or lower with plasticisers or superplasticisers providing flexibility can be mixed as required on site. (Higher powered motors may be required).

- High Speed. The vortex action inside the mixing tank rapidly assimilates the powder materials into the mixer. This results in the mixing of a batch in as little as 15 seconds. The through-put far exceeds that of other mixing technologies. With an experienced operator the cycle of charging, mixing and discharging the mix can be kept down to one minute.

- High Shear. With a discar tip speed of 26.5 metres/sec (2100 rpm) the high rate of shear results in a mix that is fluid and stable enough to be pumped over considerable distances, and it will permeate uniformly in to voids.

- Best for Bentonite. Colcrete colloidal mixers are very efficient at mixing Bentonite and other clay products as the process accelerates hydration and produces a more stable product. Mixed Bentonite permeability is lower than competing systems.

- Cost savings. The combined effect of the highly efficient mixing action and the ability to mix low water/cement ratios allows for reductions in the cement content for a given strength requirement. Thus, cement may be replaced by less costly filler such as sand, pulverized fly ash or more modern environmentally friendly filler materials.

- Optimum mixing. The unmixed slurry is repeatedly re-circulated through the zone of high shear within the mixer. This breaks down the clusters of dry particles (agglomerates) and ensures maximum dispersion of fluids and solids.

- Pressure discharge. The pumping action of the mixer enables rapid transfer of the mixed slurry out of the mixer and directly to the agitation tank. No additional slurry pump is required.

- Simple Cleaning. The unique design ensures the mixer is cleaned very easily with no excuse for operators leaving grout to dry in hoses etc.

- Reliability. The combination of robust design, very few moving parts, and readily availability of spare parts ensures long life and reliability for the equipment.

- Integrated Designs. Our designs place grout mixing, agitated storage and pumping on one compact platform with integrated functions. If desired, a dry bulk cement storage and dispensing system can be integrated with the mixing and pumping system.

- Ease of Maintenance. Our mixers have been designed with easy access cleaning ports at critical locations and other features which reduce the likelihood of maintenance problems.

- Low Risk Investment. Colcrete colloidal mixer and pumps have been tried and tested over many years and for many applications. If you have an application, chances are we have seen it before!

Mixing Tank

Mixing Tank

The mixing tank, besides holding all the ingredients, also acts as a centrifugal separator. The centrifugal action of the circulating material spins the unmixed, thicker grout towards the outside of the tank whereas the lighter portions of the mix, i.e. the water and partly mixed grout, move inwards towards the throat of the tank and into the colloidal mill. Once through the mixer this lighter material is discharged tangentially into the outer part of the vortex thus blending with the thicker, unmixed grout. Multiple passes through the rotor produce thicker and thicker grout until the entire mix becomes uniform and the centrifugal action can no longer separate differing densities. At this point the surface of the vortex has a smooth, uniform appearance.

Feed Box

The feed box to the rotor housing is of ample proportion to ensure large lumps of unmixed cement at the start of the mixing cycle are able to pass through to the rotor. These lumps can be quite sticky on the first pass before being broken up.

Control Valves

The output from the colloidal mill is split into two paths. Either the slurry is redirected tangentially back into the drum, to help create the vortex action, or it is discharged. Simple pneumatic or manual pinch valves are used to control this flow.

Mixing Tank

Mixing Tank