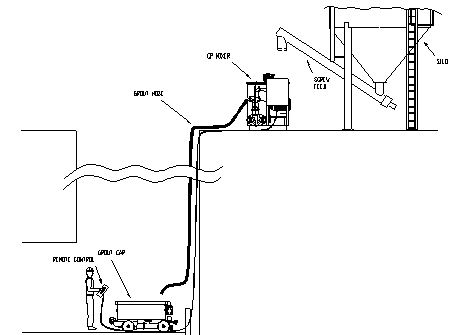

The system is primarily designed for producing grout for the back filling of ring segments. The mixer illustrated below comes complete with automated weigh batching which controls the entry of the water and up to three other materials. Screw feeds from silos or conveyor drives plug directly into the control panel which controls the delivery of the material. This system can be operated by remote control so that an operator at the bottom of the shaft can call for a batch of material and discharge it into the grout car. When the discharge is completed the mixer takes in more water ready for the next batch.

Tunnel Grout Mixing System

All Colcrete automated mixers allow full manual control of operations to ensure that mixing can continue in the event of damage to the automated system.

| Model | Max. Output (M3/HR) | Batch capacity (Litres) | Colloidal Electric (KW) | Paddle Electric (KW) |

| Colmixer CP6000 | 20 – 25 | 6000 | 44 | 11 |

| Colmixer CP4000 | 17- 22 | 4000 | 44 | 7.5 |

| Colmixer CP3000 | 15 – 20 | 3000 | 44 | 5.5 |

| Colmixer CP2000 | 10 – 12 | 2000 | 22 | 5.5 |

| Colmixer CP1500 | 9 – 11 | 1500 | 22 | 4 |

| Colmixer CP1000 | 8 – 10 | 1000 | 22 | 3 |